Chair of Powerful Thinking, Tim Benson, kicks off the year with a blog reminding event power suppliers to prioritise prevention, efficiency and reductions in 2023 power plans. With new power solutions coming to the market, from large-scale mobile battery systems to hydrogen combustion generators, Tim highlights the continuing need for energy efficiency and reduction of our dependence on liquid fuels, using the ‘Power Management Hierarchy’ devised by ZAP Concepts and Hope Solutions, as a framework for best practice:

“Happy New Year to all our Vision2025 and Powerful Thinking friends! 2023 is set to be another monster of a year for our sector, with significant one-off shows in the UK including Eurovision and the Coronation, so let’s start off on the right foot with our energy planning and management.

With so many different solutions available to us, from large scale mobile battery systems to hydrogen combustion generators, it is sometimes easy to lose sight of what is really important, i.e., being more energy efficient and reducing our dependence on liquid fuels.

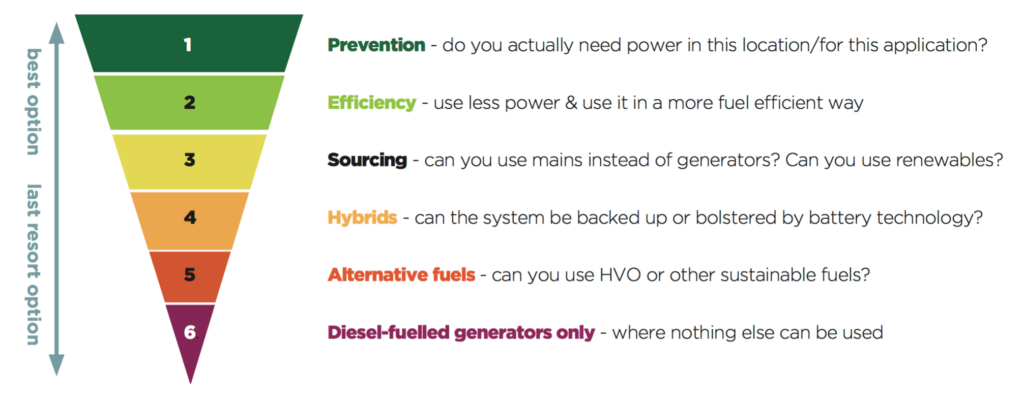

With this in mind, a good starting point is to refer to the Power Management Hierarchy, devised by ZAP Concepts and Hope Solutions.

This hierarchy is intended to help event organisers and their power contractors prioritise the most environmentally sustainable interventions available to them and can be applied to an entire event site or to individual power zones. It further relates to all phases of the event lifecycle from build to break.

Reducing Demand

We need to consider both how much energy we are using (expressed in kilowatts / kW and described as ‘the load’) and how long we use it for (expressed in hours); collectively these metrics make up the common unit of electrical consumption known as the kilowatt-hour (kWh) – which is often referred to as demand. Improving onsite energy efficiency means putting in place strategies that both reduce the load and cut the hours; these might include sourcing more energy efficient equipment, swapping out electrical catering appliances for those that run on alternative fuels like gas, introducing inline timers that switch circuits on and off, the introduction of photovoltaic sensors that activate circuit contactors when light levels change, and using the start/stop timer function on generator control panels.

Understanding Load Profiles

Load profiles are patterns in energy usage, typically viewed across a 24-hour period or longer. Most commonly at events we see asymmetric load profiles: periods of

high usage sandwiched between periods of low consumption, which are known as base loads. Where a power contractor has previous experience of an event, they will be better placed to understand the nuances of the site load profile and plan accordingly for base load management; common strategies include hybrid power generators that manage periods of low load from the energy stored in their batteries, syncing smaller diesel generators with higher capacity ones and designing site layout so that applications that require 24 hour power are grouped in clusters.

Power Advancing

Collecting accurate information on demand and load profiles in the advancing stages can be challenging, but remains absolutely crucial if efficiency is to be improved. It requires production teams, their contractors and suppliers to provide comprehensive equipment inventories and data on energy consumption, together with switch on/off schedules for the full lifecycle of the event. More often than not, what is actually supplied is a list of electrical connection requirements that bears little resemblance to the actual load. Inaccurate and incomplete advancing information is one of the chief causes of inefficiencies. It leads to the oversizing of generators because specifications are based on peak loads, and wasted opportunities for introducing alternatives power solutions for base load management. Processes such as the ZAP Concept’s Smart Power Plan, that inventory site-wide electrical consumers, can be helpful in matching energy production to actual demand, allowing generator downsizing and a reduction of fuel consumed.

So, here’s to whatever 2023 chooses to throw at us and wishing you all ‘bonne chance’ for the coming year – it is going to be brutal!”

This guest blog originally appeared in the January 2023 Vision: 2025 newsletter. Sign up to receive monthly event sustainability news, case studies and guest blogs direct to your inbox www.vision2025.org.uk