Tim Benson, Chair of Powerful Thinking, takes on tour emissions in his latest blog: With carbon emission from touring travel hitting the headlines as the industry gears up to restart Tim points out that emissions from power provision are still a crucial factor to address in order to move towards goals for net zero productions. Tim warns against reliance on a straight switch to alternative fuels alone and urges Production Managers and stakeholders to embrace efficiencies through broader energy management plans that incorporate better advancing and scheduling, wider use of mains supplies and on-site renewables, battery deployment and crucially, a behavioural step change.

“Touring is the latest live sector to be scrutinised under the sustainability microscope and quite rightly so. Its nomadic nature, whereby artists and their entourages clock up thousands of miles across multiple territories in the shortest timescale possible, results in huge levels of travel emissions. You don’t need to be a sustainability expert to understand the gravity of this, its impact is crystal clear to even the most ardent of fans and this is exactly what is driving change – audience perception. Cue the Live Nation Green Nation Touring Initiative, which cites audience sustainable lifestyle choices as a key driver for its roll out, and last week AEG Presents followed suit, announcing the formation of its Climate Positive Touring (CPT) group.

And yet there are so many other factors that contribute to tour emissions, many of which can be mitigated through technological interventions. However, there’s something more insidious at play here, a behaviour driven barrier that is thwarting the best efforts of those championing sustainable tour production. It boils down to a deep-rooted reluctance amongst the touring community to alter their production practices. This community is made up of multiple stakeholders, from TMs to LDs, label representatives to commercial partnership teams, all of whom consider that the end justifies the means. They are tasked with producing the shows and will go to almost any length to ensure their remit is delivered without compromise. The one requirement all these stakeholders share is power and generally they want an uncapped supply right there, right then. If touring is genuinely looking transition to more sustainable power provision, then this sort of approach has to change.

Luke Howell, Founder and Director of Hope Solutions, concurs with this, stating: ‘Energy impacts from touring can amount to up to 1/5th of all carbon emissions or over 60% of non-travel related emissions. Dealing with this is often met with disinterest by those who have the ability to actually instigate change and there is a huge amount of inertia around this issue. This is partly due to a lack of understanding of the topic – fair enough to a point as not everyone is an expert on it – and an overreliance on contractors to sort out the solution for them. Change is coming but slowly and sadly it is still seen as easier by many to adopt business as usual approaches (over spec’d diesel generators) than it is to look at making things more efficient.

It is clear from Powerful Thinking’s work with the Touring Production Group (TPG) in the UK and Touring Professionals Alliance (TPA) in the US, one of the main barriers to sustainable tour power is a reluctance to use mains supplies. Many Production Managers want separated power supplies for show tech, i.e. generators, because they are concerned about the reliability and stability of mains feeds. They also argue that the house feeds are often inadequate for their show peak power requirements. The solution here is simple, consider allocating energy budgets to different stage disciplines based on the available mains power supplies and, where these are found wanting, peak shave them with largescale batteries to avoid having to bring in generators. The battery systems can also support a UPS function, bridging the changeover from mains to generator supplies in the event of grid power outage.

Communicating the tour’s energy reduction objectives to all stakeholders, including crew caterers, tour bus operators, sponsors, artist liaison reps etc, and consulting with them on steps they can take to minimise their energy consumption, is crucial too. Working with them to choose the most energy efficient equipment and, therefore, reducing the overall show power requirements, will open up greater opportunities to use a renewable energy mix. This mix might incorporate renewably certified mains supplies, onsite renewables like venue solar or biomass, high storage capacity battery solutions and back-up generators running on biofuels.

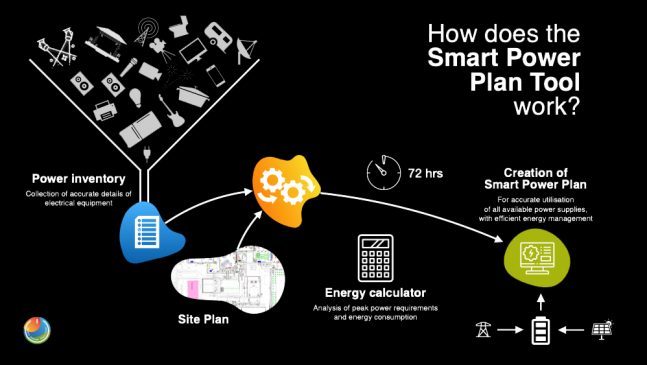

During pre-production, more time and resource should be devoted to power advancing. Apps, such as the ZAP Concepts smart power plan tool, are now available to support production teams in calculating their power and energy requirements and this will ensure on-site generation is matched to actual consumption, resulting in financial savings and quick environmental wins.

Monitoring at distribution level to ensure you understand how power is being used and when peaks are likely to occur, is also invaluable. Instead of sticking rigidly to a single power management plan, this kind of data can be used proactively to make ongoing improvements throughout the tour lifecycle.

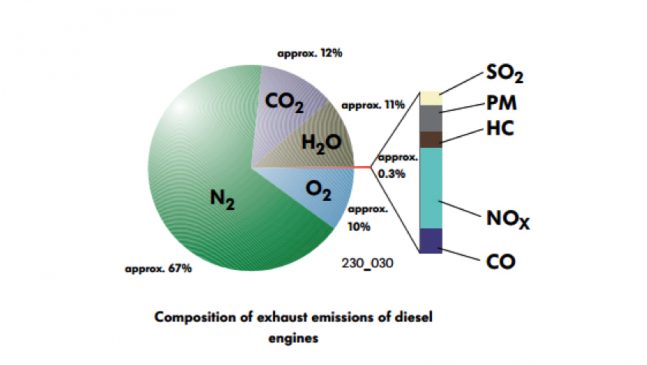

I’m going to end with a stark warning for those who think this sounds too involved, when really all they need to do is switch from diesel to biofuel. Surely a biofuel solution makes all the above erroneous and it no longer matters how much energy they are consuming? This is green wash in its worst form, because it sidesteps the main issues around energy efficiency, namely consuming less power and using it more responsibly. Yes, biofuels produce less greenhouse gases (GHGs) but they still emit high levels of localised air pollutants. They are not a renewable energy source, on the contrary they are a low carbon liquid fuel. Neste, the principle global manufacturer of HVO, often refers to its product as ‘renewable diesel,’ but this is simply a marketing term and has no scientific basis.

If you are planning to promote your tour as sustainable because you are using biofuel or hydrogen fuel cells, you are on a hiding to nothing and deserve all the flack you get! These solutions deployed in isolation mean virtually nothing, they have to be part of a broader energy management plan that incorporates better advancing and scheduling, wider use of mains supplies and on-site renewables, battery deployment and crucially, a behavioural step change.”

This guest blog originally appeared in the May 2021 Vision: 2025 newsletter. Sign up to receive monthly event sustainability news, case studies and guest blogs direct to your inbox www.vision2025.org.uk